Artwork Requirements and Technical Specifications:

We require high resolution (vector) digital artwork in one of the following formats..

Adobe Illustrator CS5 or earlier files (all fonts must be outlined)

EPS file (all fonts must be outlined)

PDF file (all fonts must be outlined / embedded)

Photoshop (300 dpi minimum at 100%) 1 color print ONLY

JPEG (300 dpi minimum at 100%) 1 color print ONLY

If you are having difficulties sending your artwork in one of the above formats, please email the artwork file to info@mauibrownbag.com or contact one of our Custom Bag Specialists at (808) 658-5175 for help.

Pixilated files such as TIF, BMP, JPG, GIF and PNG are not appropriate for print jobs that require printing in spot colors because they can’t separate properly for printing. There is a fee of $75.00 / hour for recreating the art in vector format. A Maui Brown Bag representative will contact you with an estimate before the work is started. We will give you (via email) the completed vector art for your future use on other projects.

Artwork Submission:

Art can be submitted the following ways:

Emailed to: info@mauibrownbag.com

Mailed to :

Maui Brown Bag

Attn: Art Department

PO Box 1677

Lahaina, HI 96767

If mailed, artwork must be one of the above mention files on a CD. Please include output of the artwork so we can reference when we open the file from the CD). Please do not send camera ready art that has been output. We can only accept digital art. Please contact a Maui Brown Bag rep for further assistance.

We can recreate your art for you. There is a fee for cleanup of art files that do not meet print quality standards. A Maui Brown Bag representative will be happy to offer an estimate before the work is started. We will give you (via email) the completed vector art for your future use on other sections.

Printing Process

When we imprint our bags we use a number of different printing methods depending on a number of factors. Type of bag, quantity of bags, and number of colors to be printed are a few examples of determining factors. Here are some brief explanations of the different processes we use.

Post printing: This is a process in which we take bags that have already been manufactured (finished bag) and run each bag through an ink printing press 1 bag at a time. This is used with small quantities of paper and plastic bags. Inks are used on this process.

Usually 1 to 2 colors with this process. When printing 2 colors we will need a minimum of 3/8? between colors to allow for movement when printing the 2nd color.

Limitations:

- No light colors printed on dark bags

- No edge to edge printing

- No tight registration

- No heavy coverage or reverse outs

Print and converting: This is a process in which we begin with large rolls of paper or plastic. These rolls are run through printing presses where the material is printed with the specified colors and art. The printed material will then pass through bag machines which will fold, cut, and seal (convert) the material into a finished bag. This process is used when printing larger quantities of paper and plastic bags, starting around 3,000 bags. This is also known as Spot Printing.

Spot printing is when specific colors are chosen to be printed on the bags. Colors are picked from the PMS chart (Pantone Matching System). This is the universal color chart in the printing industry. If we do not have your specific PMS color in stock a PMS ink match charge may be applied to your order. Please ask your Custom Bags Inc Representative and they can assist you.

We can print up to 4 colors with this process.

Limitations:

- No light colors printed on dark bags

- Please ask your Maui Brown Bag Representative about your project and they can assist you with the limitations; if any

Hot Stamping: This is a process in which we take bags that have already been manufactured (finished bag) and run each bag through a hot stamp machine 1 bag at a time. This is used with small quantities of paper and plastic bags. Foil is used in this process instead of ink.

Usually 1 to 2 colors can be stamped with this process. When printing 2 colors we will need a minimum of 3/8? between colors to allow for movement when printing the 2nd color.

Limitations

- No edge to edge printing

- No tight registration

- No heavy coverage or reverse outs

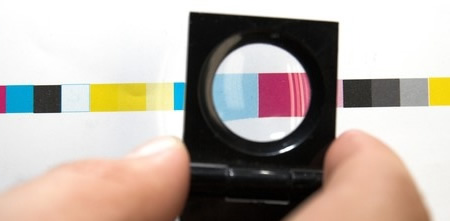

Process Printing: Process printing is used when the art is greater than 4 colors. The art is usually very intricate or complicated with multiple colors with gradations or screens. For example if we wanted to recreate a color photo on a bag we would have to print 4 color process. Process colors are CMYK, (cyan, magenta, yellow, and black). With this process the colors are created when very small transparent dots of each of the above colors, in varying percentages, are laid on top of one another. The different percentages of the colors on top of each other create the different colors required in the artwork. Process printing is always done on large rolls of paper or plastic (print and convert). These rolls are run through printing presses where the material is printed with the specified colors and art. The printed material will then pass through bag machines which will fold, cut, and seal (converted) the material into a finished bag. Minimums for the above are 25,000 bags with the exception of laminated paper shoppers which are less. Please ask your Custom Bags Inc Representative for more info.

Limitations

- No light colors printed on dark bags

- Please ask your Custom Bags Inc. Representative about your project and they can assist you with the limitations; if any.

Technical Definitions

Post printing: Ink printing on bags that are already made (see Printing Processes for full description).

Hot stamping: Another form of printing on bags that are already made. This uses foils that are adhered with heat instead of ink (see Printing Processes for full description).

Spot Printing: Printing single colors indicated in the artwork (see Printing Processes for full description).

Process Print: Printing using CMYK (Cyan, Magenta, Yellow, Black) for very intricate complicated print jobs with more than 4 colors (see Printing Processes for full description).

Printing and Converting: Printing on rolls of paper or plastic and converting the material to bags in the same process (see Printing Processes for full description).

Ink Coverage: Percentage of the surface of the bag that is covered by ink.

PMS Color: PMS (Pantone Matching System) is the universal color chart used in the print industry.

Registration: This refers to the position of multiple colors in a piece of artwork. If a piece of art has 2 colors and the 2 colors touch some where on the art, this is considered tight registration. We use the term registration because the colors must appear in the same spot every time.

Lead time: Amount of time for a job to be produced.

Over / Under Run %: Over and Under run is a percentage of the amount of bags that the job could end up over the initial quantity ordered or under the initial quantity ordered (see Printing Processes for full description).

Domestic Production: Bags produced in the USA.

Overseas Production: Bags produced in Asia.

LDPE: Low Density Polyethylene.

LLDPE: Linear Low Density Polyethylene.

PP: Polypropylene.

HDPE: High Density Polyethylene.

Formulas for calculating Weight per 1000 bags:

This formula is used to calculate the minimum number of bags needed for a run.

Material type: LDPE, LLDPE, Polypropylene

L X W / 3 X 2 X Gauge / 10 =

12 X 12 (144) / 3 (48) x 2 (96) X 2 gauge (192) / 10 = 19.2 lbs / 1000

19.2 lbs per 1000 / 500 lbs = 26,000 bags

HDPE L x W x .0686 x gauge = Weight per 1000 bags

12 x 12 (144) x .0686 x 1.5 mil = 14.82 lbs / 1000